Electroplating also known as electrodeposition is an electrolytic process.

Copper is electrodeposited for numerous engineering and decorative applications, requiring a wide range of mechanical and physical properties for the customers' diverse needs.

This process can be used to give components increased wear resistance, corrosion protection or aesthetic allure, increased thickness and anti-galling properties.

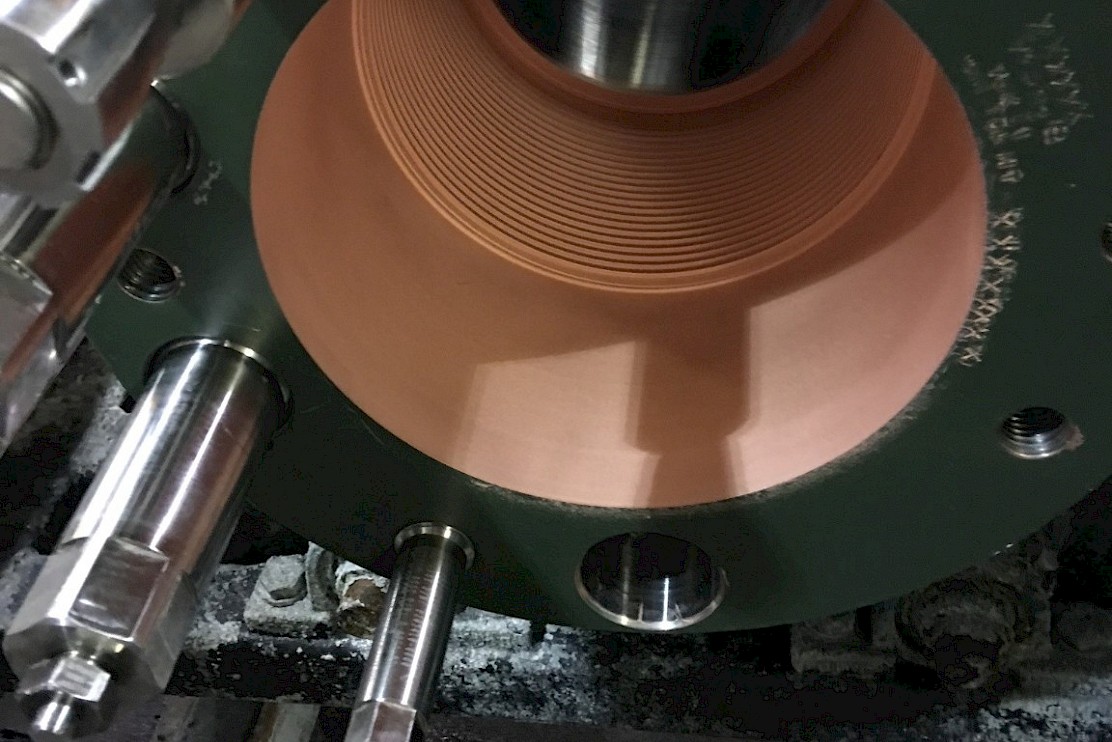

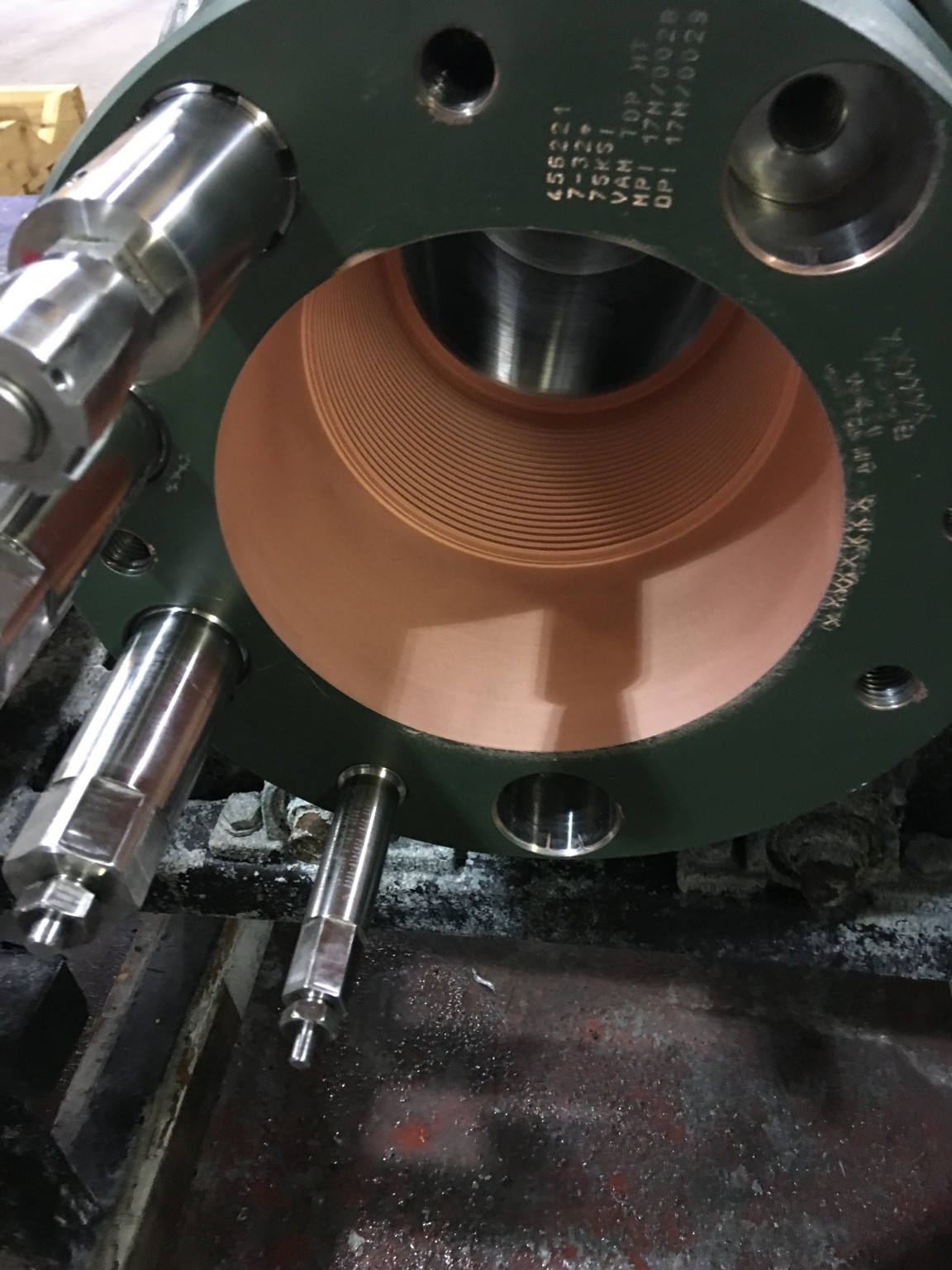

Plating from high-efficiency solutions on selected surface metal substrates, such as LAS, 9Cr, 13Cr, Inconel, Monel, HSLA, materials etc, prevents galling in oil country tubular goods (OCTG) equipment.

Thickness requirements achieved from 5-25 microns in general and up to 100 microns for recovery of components during a refurbishment or rescue project.

In the main, Argosy apply copper plating to premium threads to prevent galling.

The application of copper and multi-disciplined coatings on a single component is one of our strengths.

Working to British and military standards along with customer specifications. Argosy deliver a quality job, right first time every time.

Approvals

VAM, TENARIS, HUNTING, HALLIBURTON, BAKER and others for the copper plating of their premium thread connections along with other company approvals.

Benefits

- Anti-galling

- Conductivity

- Soft, malleable metal

- Corrosion resistant

- Cost effective

- Stop-off for selective heat treating

- Applied as an undercoat for other deposits to protect base metal or promote adhesion

- Recovery

Application method

Immersion and 'brush'. Strip and recoat. De-embrittlement.

Typical applications

- Wireline components

- Drilling components

- Tubulars & casing

- Hangers

- Crossovers

- Subs

- Mandrels

- Range 3 joints

- Large diameter and complex geometric components

- Seals and Gaskets

- Assemblies